This is a proactive maintenance system for hospital oxygen generator

업체관리자

view : 5580

This is a proactive maintenance system for hospital oxygen generator

(by Oxus Co.,Ltd.)

1. Current installation status of the OXUS oxygen generators for hospitals

OXUS oxygen generators for hospitals are currently installed and operated in about 350 small and medium-sized hospitals, in which the product specification is mainly 3.6Nm3/h (60LPM) or less.

The greatest advantage of our module-type product is that it significantly reduces the maintenance cost during the product service life compared to other twin tower type oxygen generators do, and that even non-experts can have abilities to resolve most of the product issues only with simple training.

In addition to the easy installation and advantageous follow-up service of the product, OXUS is providing prompt maintenance service even before our customers notice the product issues by applying the real-time central monitoring system to every equipment that is installed and operated in the hospitals over the country.

2. ICT (Information Communication Technology) Central Monitoring System

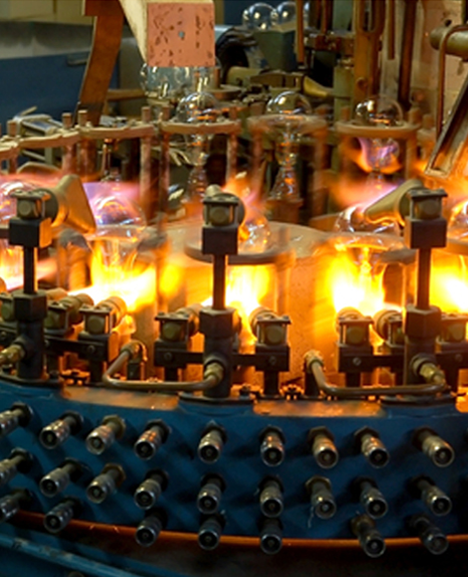

2.1 A flow chart of general oxygen supply within a hospital

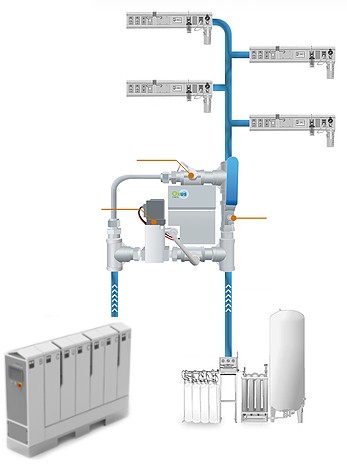

2.2 What is the ICT Central Monitoring System?

Our company’s monitoring system offers real-time monitoring of all products that are installed and operated in many institutions and reports the result to the customers. Also, real-time reporting of the oxygen generator’s purity and total running time is provided to the OXUS central server or to the customer’s computer through the Internet connection.

2.3 System configuration

2.4 Running program image

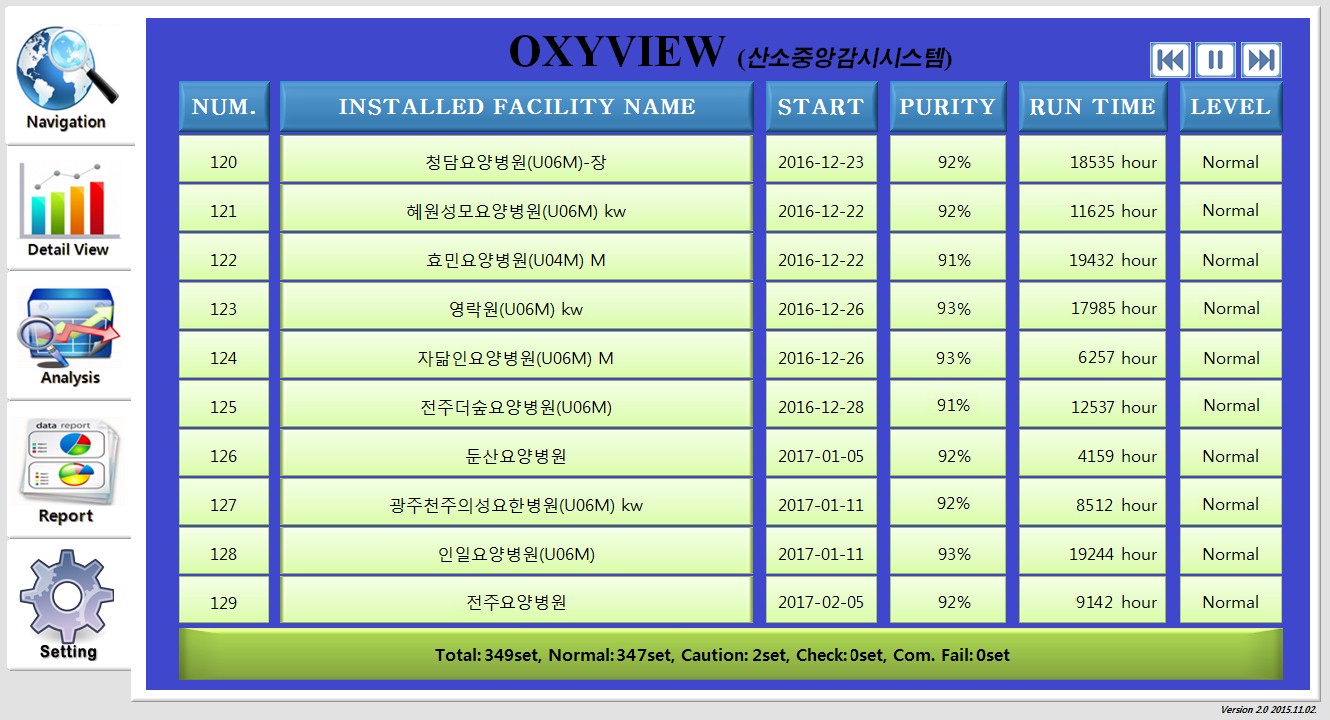

(1) Navigation tool: Provides real-time monitoring of all products that are operated in a total of 349 installation sites.

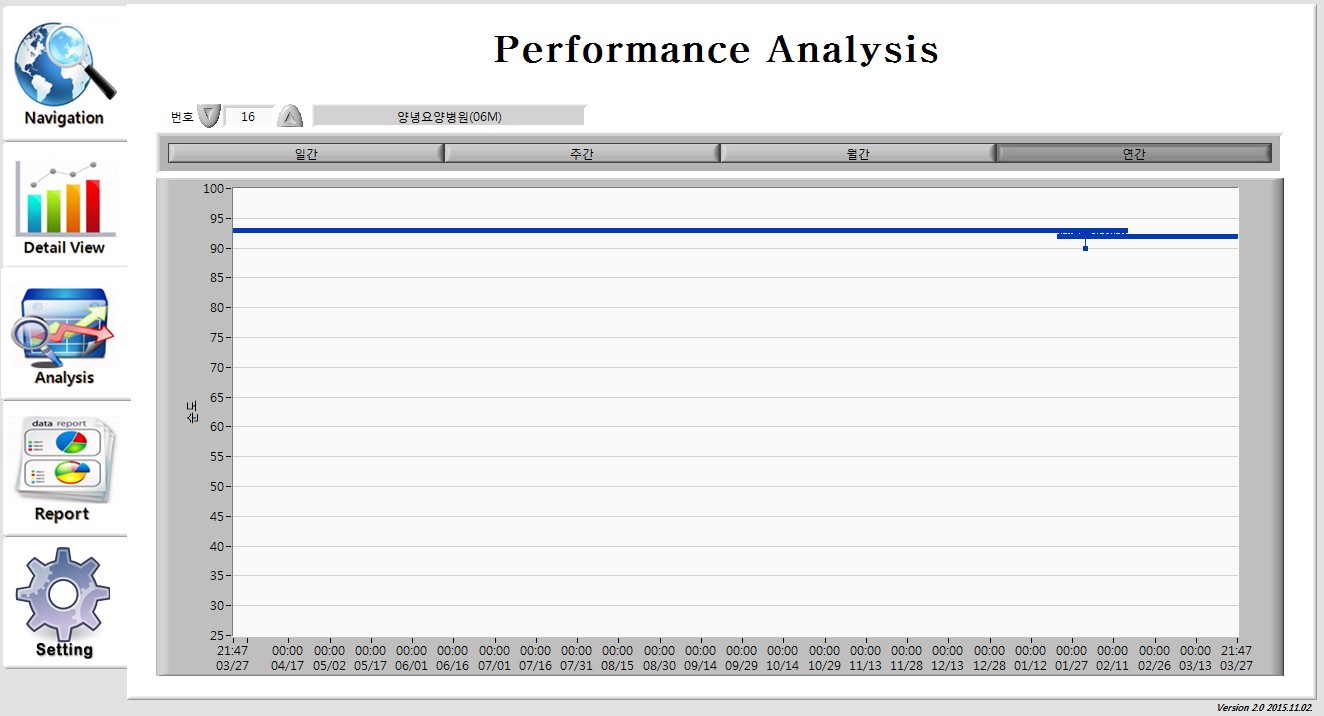

(2) Analysis tool: Able to examine the trend in purity change as daily, monthly, and yearly units.

(*The graph above shows the purity of the product which was dropped into 92% from 93% on Feb. 11)

2.5 Advantages of the ICT Central Monitoring System

The central monitoring system reports the device performance to the customers once a month.

Also, by predicting a time when the device performance would be degraded, it notifies the customers about it in advance so that they can have follow-up care before the actual issue occurs.

With the ICT Central Monitoring System that allows advanced follow-up actions, we offer our customers a high level of product credibility.