HOME > APPLICATIONS > WATER TREATMENT

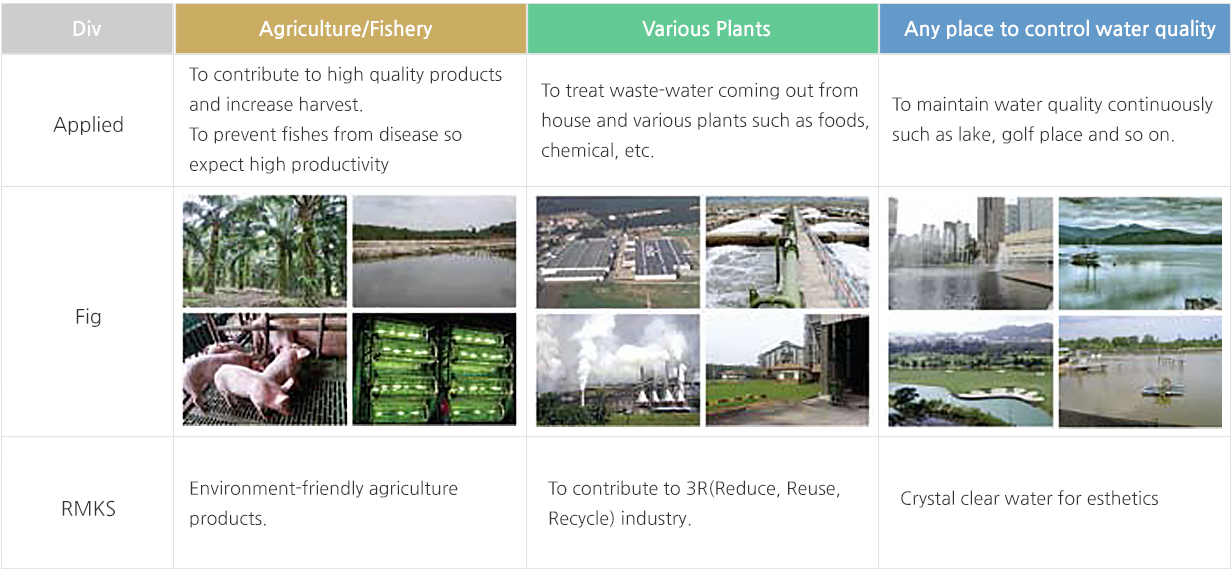

The project is to supply high-purity oxygen required by fish and shellfish in the aquatic cultivation industry

we are opening a new door toward the modern industry of the 21st century in the field of wastewater treatment by DO control.

It is a well-known fact that the only way to improve water quality is to increase the amount of dissolved oxygen (DO) using high-purity oxygen. Effectively dissolving the oxygen into the water requires a high

level of technical expertise and experience. After five years of trials and errors. JuvAir finally found a way to effectively provide oxygen into water. Now, more than 150 aquaculture farms in Jeju island benefit from our

stat-of-the-art technology.

Based on our experience, we apply our technology into various of fields, including wastewater treatment and deodorization. Thereby contributing into advancement of the industry and improving the quality of live through the

application of our technology. JuvAir continue to do research and development(R&D) on high-Efficiency Oxygen Dissolver technology, so that we could always leading the global market.

Thank you.

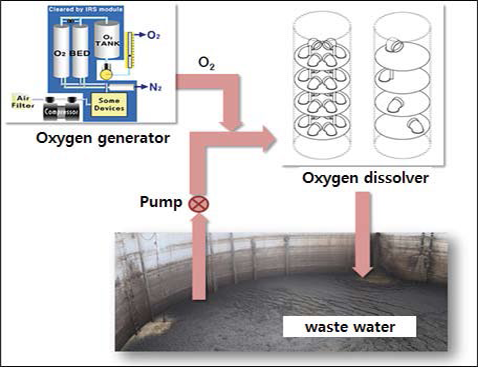

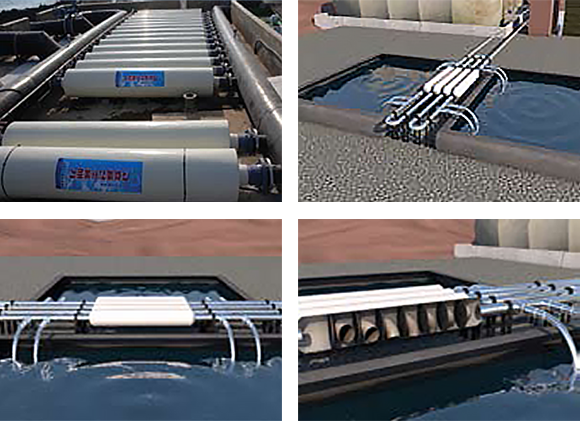

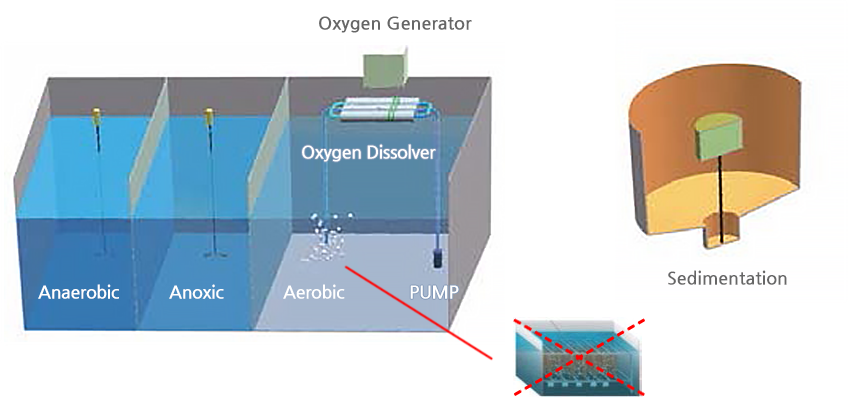

JuvAair technology is using closed type pure Oxygen injection System into the WasteWater to reduce the Biochemical Oxygen Demand (BOD), Chemical Oxygen Demand (COD), - TotalSuspended Solids (TSS) as Well as Total Organic Carbon (TOC) by Oxidation processes.

When the wastewater flow into the System an Oxygen dissolved by a circulation pump in an aeration tank, Oxygen With ConCentration of 90% or higher is injected into the entrance of the dissolver in Order to SuperSaturate the Oxygen Concentration up to 400% or higher.

Then, Wastewater is repeatedly returned to the aeration tank to increase the dissolved Oxygen (DO) of the Wastewater and provide the Sufficient DO to microbes for their metabolism for the Contaminants removal processes.

Simple DO Control

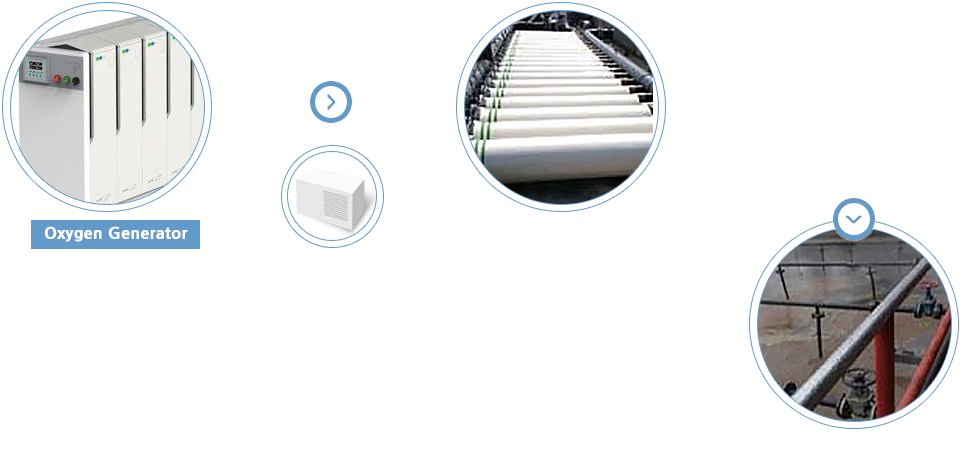

Oxygen DiSSolved System is produce by Our proprietory Oxygen generator. This Oxygen generator is possible to adjust the dosing according to the Water Condition.

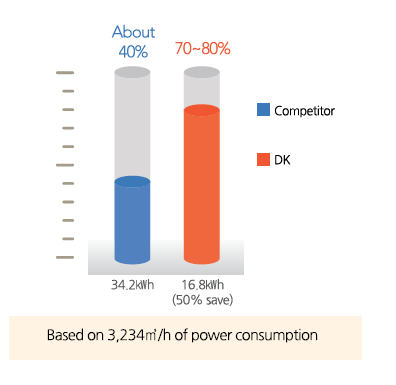

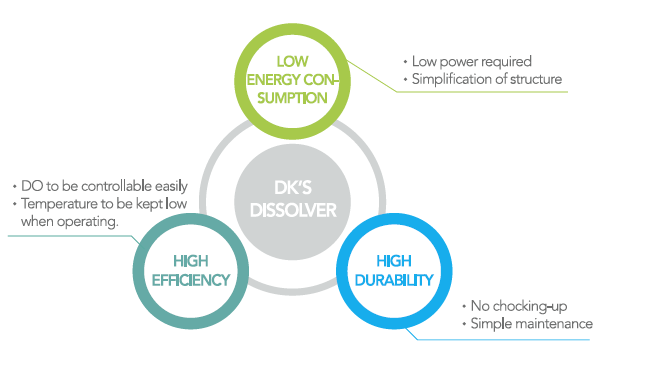

LOW energy Consumption

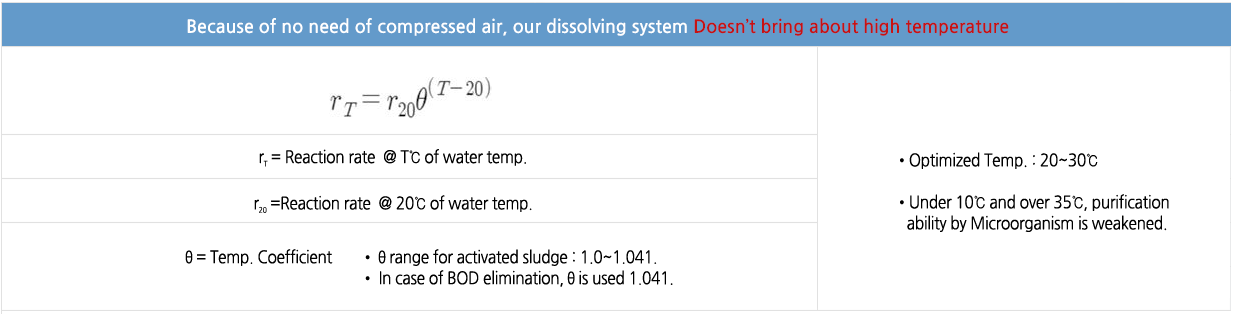

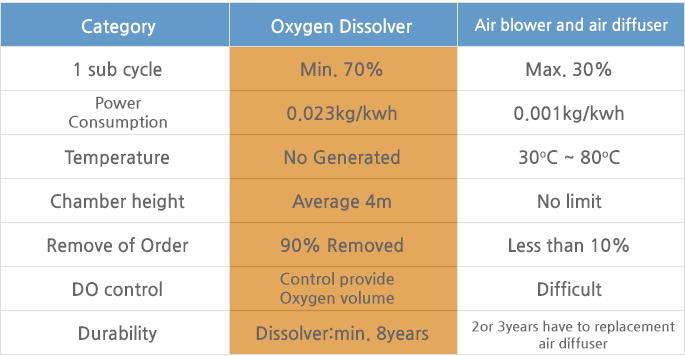

Electricity Consumption is 500W per unit. It is Compare to air diffuser and blower it Can Save electricity minimum of 50%.

High efficiency Oxygen dissolve

Oxygen Dissolved System maximizes the dissolution efficiency up to 80% with provide oxygen Concentration approximately 80% and Saturation Over 400% of Oxygen thru Strong turbulence in Oxygen dissolver in the closed circulation System. This innovative System overcomes an uneconomic issue and Complicated Structure of Conventional aerator System.

1. By using Pump, Wastewater With Oxygen transfers to the Oxygen dissolver.

2. Oxygen to be dissolved by turbulence in Oxygen dissolver.

3. WasteWater with dissolved Oxygen turns into aerobic tank or pond.

4. Continue circulations will Continue to increase DO concentration in Wastewater.

The oxygen generator is for generator supplies only oxygen to separate the nitrogen and oxygen in the air by a PSA (Pressure Swing Adsorption) technique. After separated, Nitrogen is discharged to air and only collected pure Oxygen and Oxygen is provided through air tube to dissolver.

Oxygen Generator

Oxygen Dissolver

Malacca river problem

Government to investigate on fishes found dead in river

Generally, Any fishes cannot live in polluted Water Over 15 ppm of BOD and lower than DO 3ppm, especially at night time more Serious. It happened to Malacca river.

Definitely, the polluted of water cause lots of fishes died in Malacca river and a severe odor.

Hereby, JuvAir is to offer a Solution for Water treatment for the polluted Water by pure Oxygen treatment.

Target is make of clean river Water using Our Oxygen System for Suitable fishes live environment.

Advanced treatment of polluted Water using to

pure Oxygen high efficiency process offered by JuvAir System is best Solution.

Proper DO level

Low energy consumption

Not effect temperature

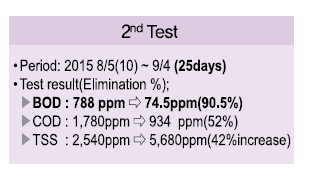

Odor with Liquefied Fertilizer

Odor in pigsty

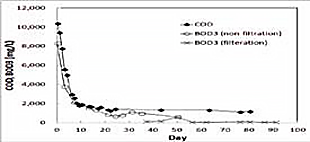

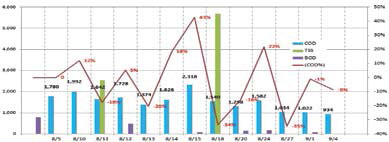

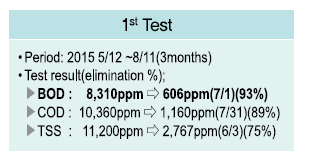

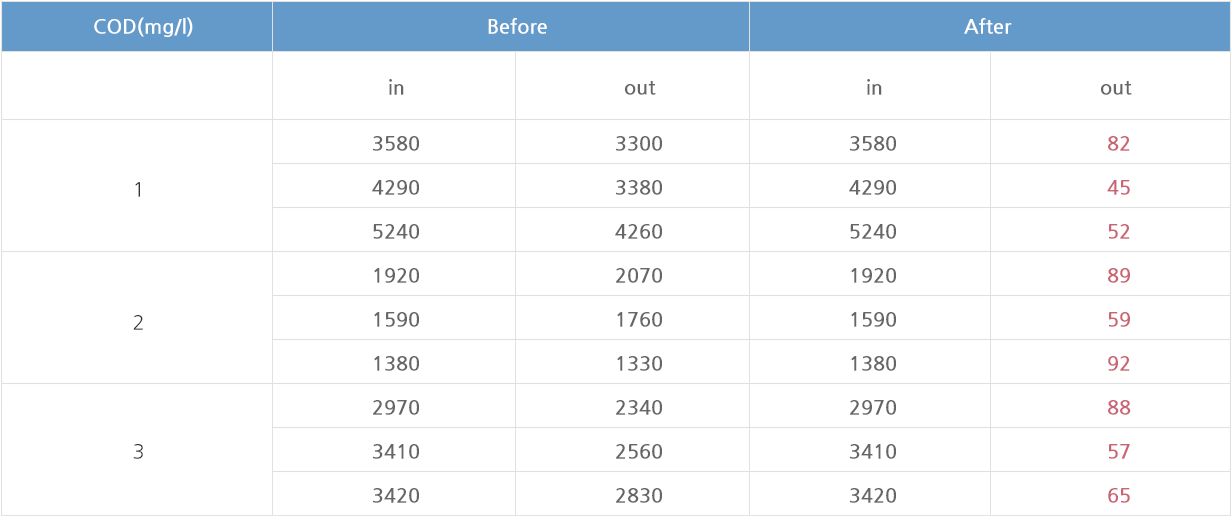

Waste water treatment data for pigsty

After JuvAir Oxygen system, removed odor 90% and reduce operation time and resolve the over load problems.

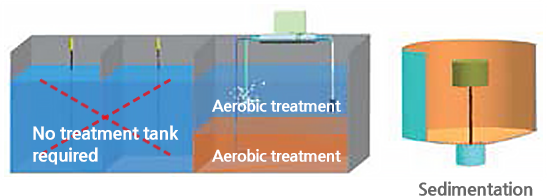

JuvAir system is very simple in installation and air diffusers are not required.

Accordingly, JuvAir system offers low installation and operation cost with good efficiency.

Fill

React

Settle

Draw

Idle

Fill

React

Settle

Draw

Idle

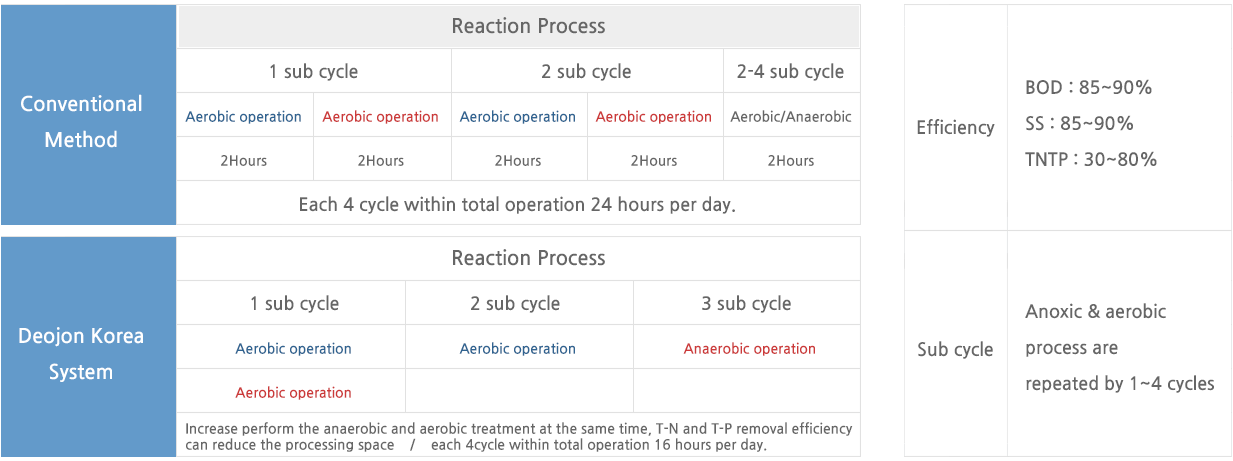

JuvAir's pure oxygen technology is compatible with the sequencing batch reactors (SBR). The technology creates aerobic conditions in the upper part of the tank, and anaerobic conditions in the lower part of the tank, which remarkably improves the treatment time and space requirements.

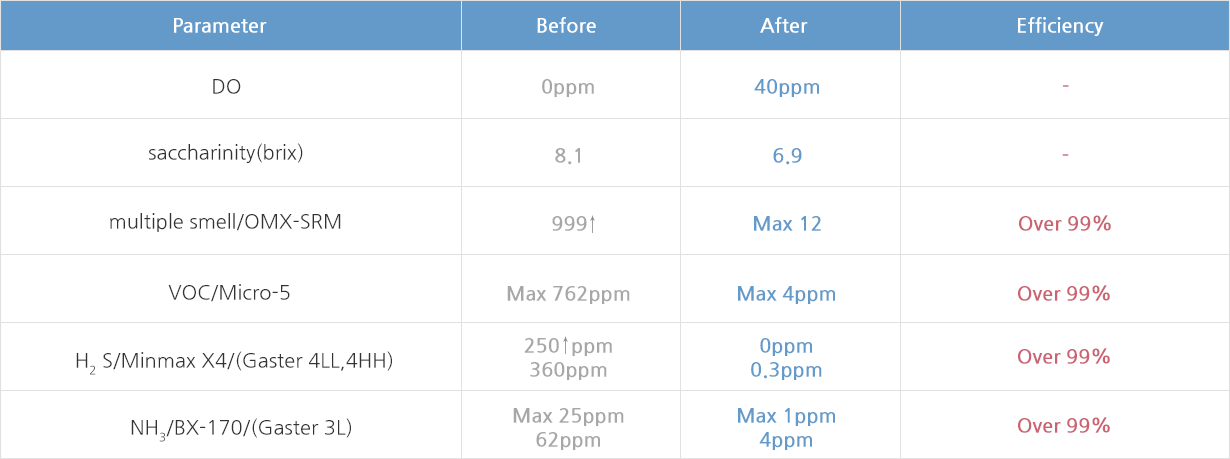

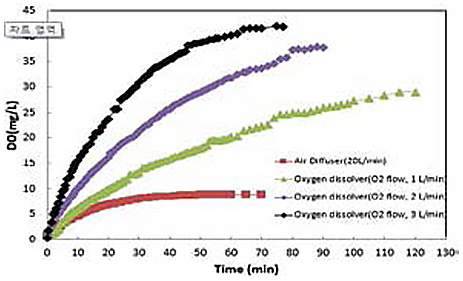

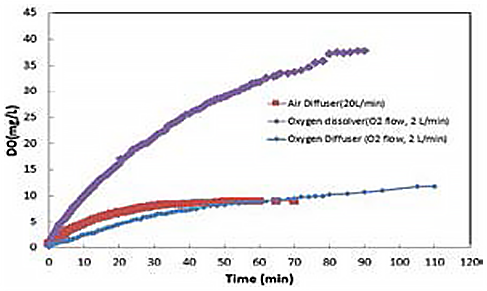

Test performed in clear water without animals and microbe

Air blower and air diffuser : Max. 10ppm (20 lpm)

Oxygen Dissolver : Max. above 43ppm (2 lpm)

Oxygen Dissolver made Oxygen concentration

7 times higher than Air blower and air diffuser.

Air blower and air diffuser

Oxygen Generator and Dissolver

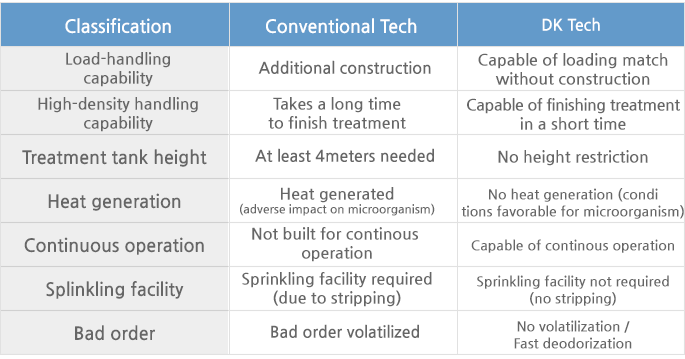

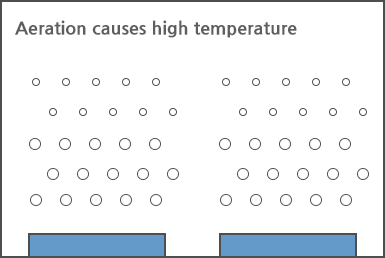

Aeration interferes with maintaining the appropriate level of the dissolved oxygen concentration.

It also generates heat, which inhibits microorganism proliferation.

The increased contamination load results in the expansion of the site area and budget increase caused by the installation of new treatment facilities.

Low Do

Inhibits microorganism proliferation, especially filamentous fungus, and lowers the sedimentation rate -> lower effluent water quality

High temperature

Increases microorganism proliferation, which inhibits the disintegration of organic matters -> no water quality improvement