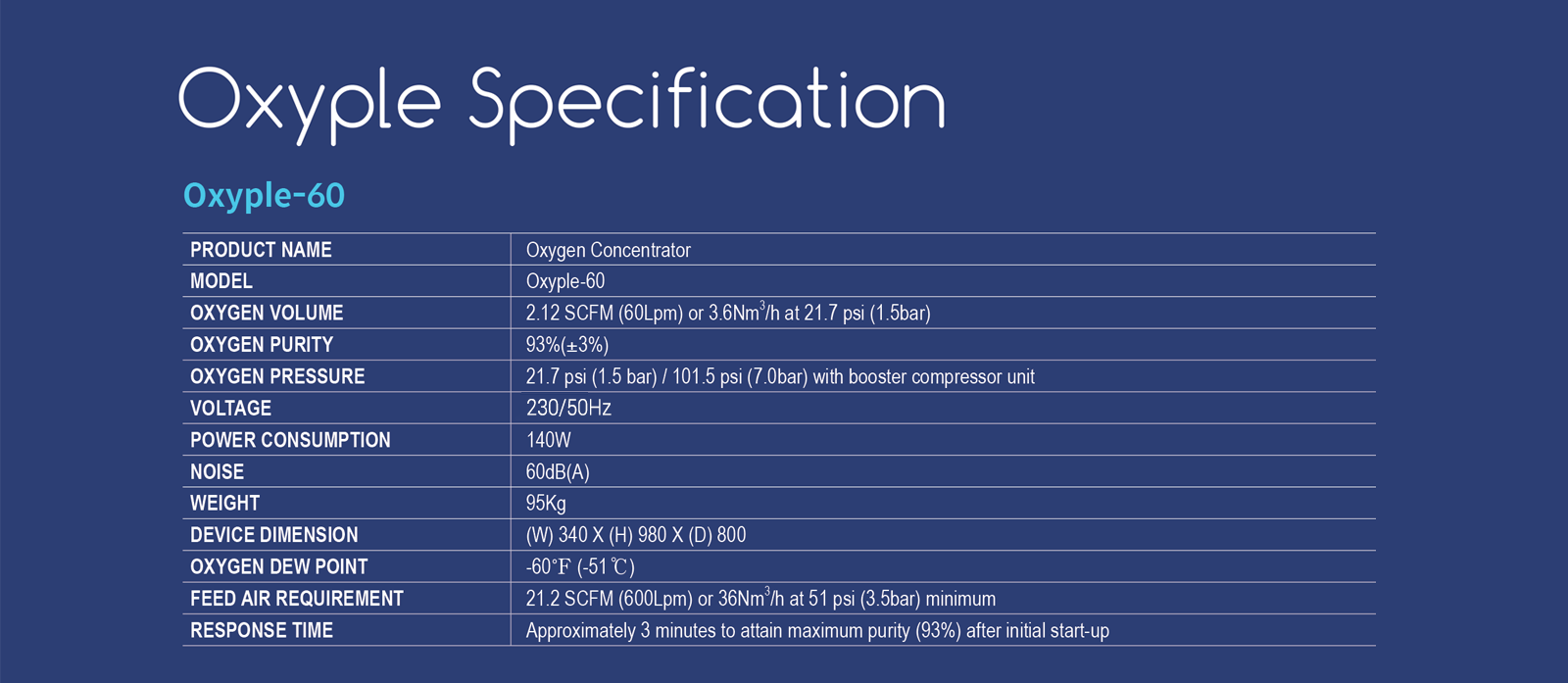

This is the flagship product of JuvAir.

Oxyple is called the 4th generation Oxygen Generator.

Burdensome initial installation cost

Oxygen production more than needed

Unnecessary power consumption

Previous oxygen generators with bulky, inconvenient and manually

controlled design are no longer good enough

Maximize your performance but minimize your cost with Oxyple.

You can build your own system by adding or removing the units based on your needs.

| 1st | 2nd | 3rd | 4th | |

|---|---|---|---|---|

| Twin Tower | Independently Small Unit | Parallel Module | Proportional Module | |

| Freed Air Pressure | High (7~8bar) | Low (2~3bar) | High (7~8bar) | Low (2~3bar) |

| O2 Discharge Controls | Fixed Control | Fixed Control | Fixed Control | Proportional Control |

| Flexibility | X | X | O | O |

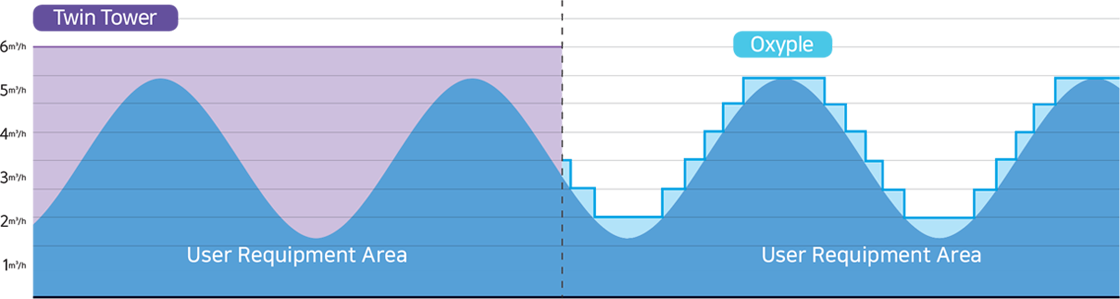

Oxyple system can configure as many oxyunits as needed depending on

O2 consumption and the capacitycan be easily adjusted.

Oxyple’s flexible configuration system is its outstanding characteristic in view of currently-used twin tower products.

Flexibility

Oxyple is a 1.2m3/h oxygen generator.

Oxyple provides 1.2m3/h to 1,000m3/h by adding oxyunit.

Available by connecting the previously installed air piping line.

Convenience

Simple structure facilitates convenient maintenance and after sale service.

A variety of options are available for compact space required for installation, minimizes spatial constraints.

A variety of alarm services requires minimal management for operations.

Economy

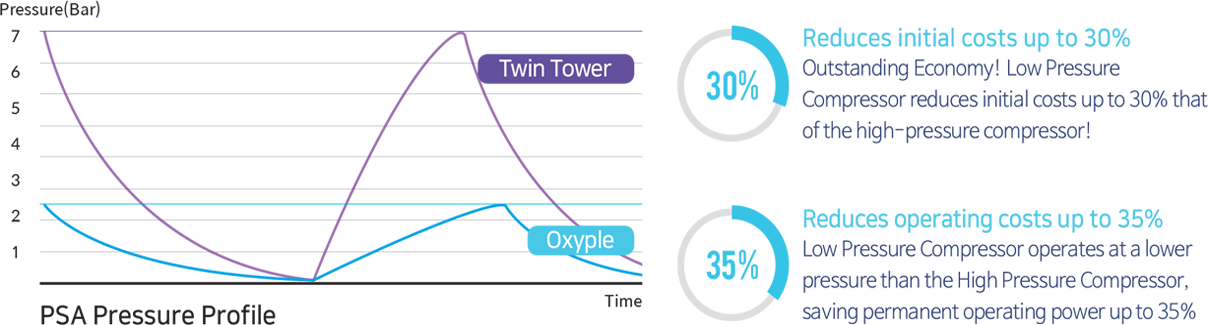

Oxyple reduces initial costs up to 30% and operating costs up to 35% of Twin Tower.

A reduction in volume can also reduce operating costs additionally.

Safety

Parallel structure of single oxyunit systems rather than simple absorption tower of Twin Tower.

Respective single oxyunit is equipped with 5 types of condition detecting sensors.

PSA process control with high altitude use(up to 5,000meter) and water

discharge function to protect water contamination of zeolite(Patent)

Fixed Control with Oxygen Demand

High Pressure PSA(Pressure Swing Adsorption)

(1st Generation)

.png)

Always operated based on fixed volume

Reduced O2 demand can result in energy waste.

Expensive electricity bil

Application of relatively high cost compressor

High operating power

High feed air crushes Zeolite, reducing durability

Proportional Control with Oxygen Demand

Low Pressure PSA(Pressure Swing Adsorption)

(4th Generation)

.png)

Discharges optimal quantity according to

O2 demand Minimize energy waste

Significant savings on electricity bil

Application of low cost compressor

Application of low operating power

Low feed air minimizes the crushing of Zeolite,

increasing durability and performance while separating oxygen

Respective Oxyunit modules can be controlled independently due to (modular) structure.

This enables variable modular control as O2 demand changes. Proportional discharge performance

provides significant savings on operating costs. This makes Oxyple unique.

All inconveniences such as space,

installation, movement

and control are blown away!

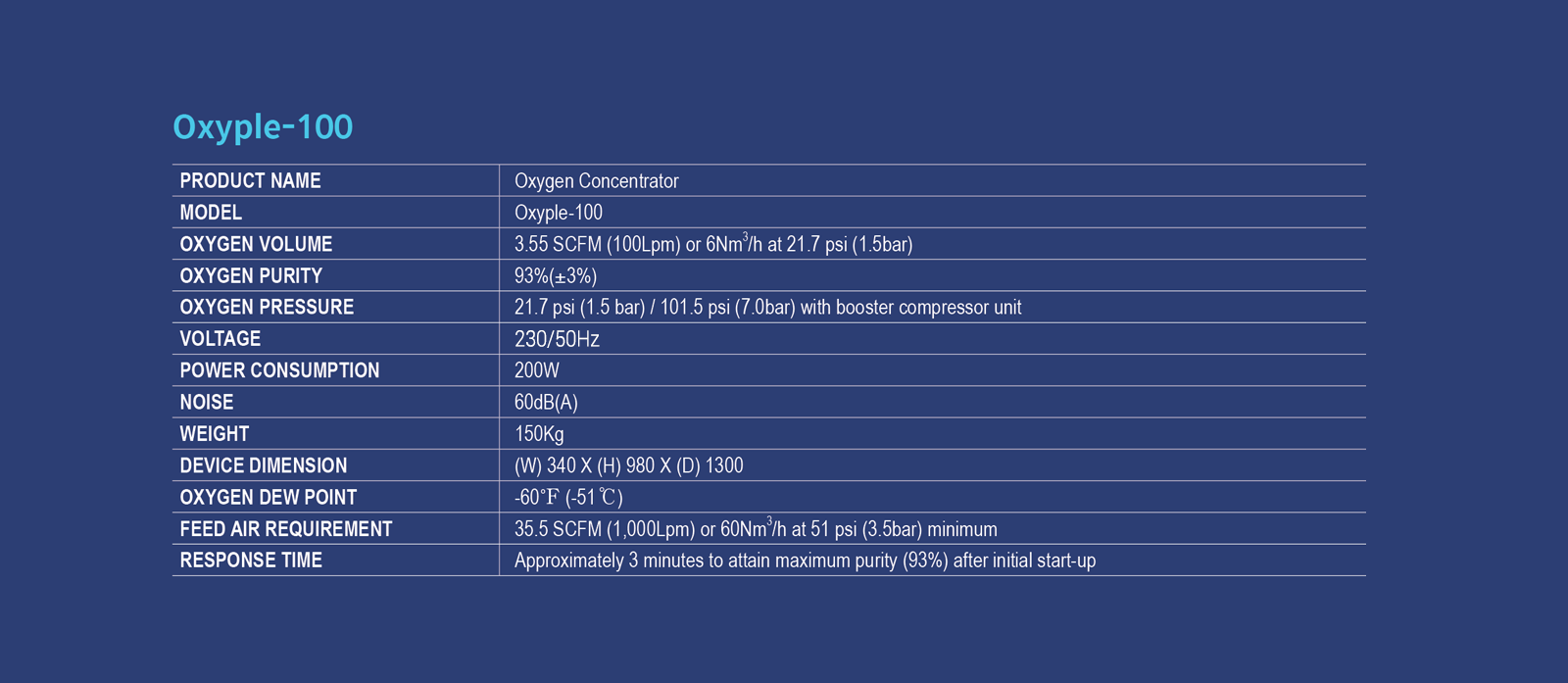

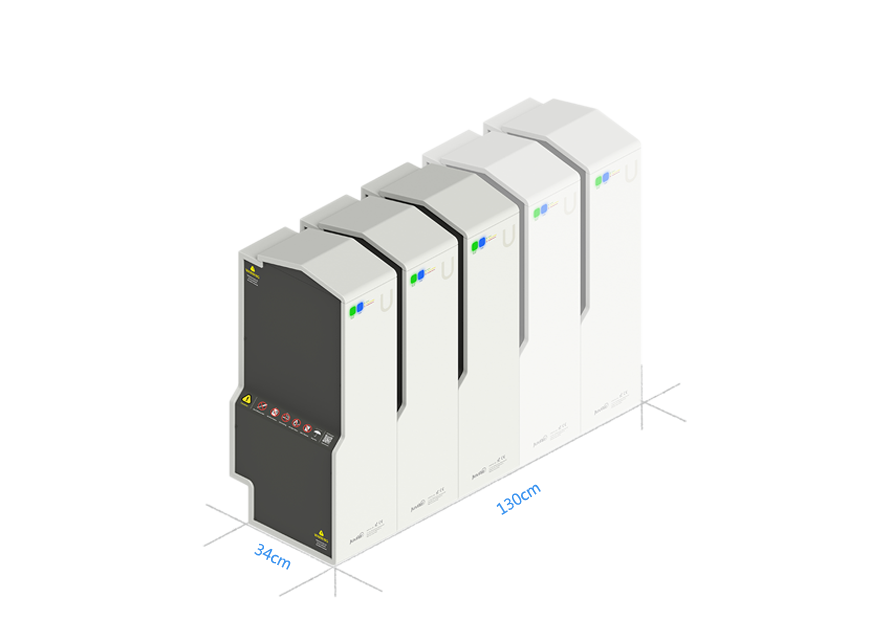

Oxyple-100 (6m3/h),

needs only

130x34cm space for installation.

The Oxyple Controller design is

highly visible and intuitive.

Oxyple’s light and simple structure

is easy to assemble,

install, and move